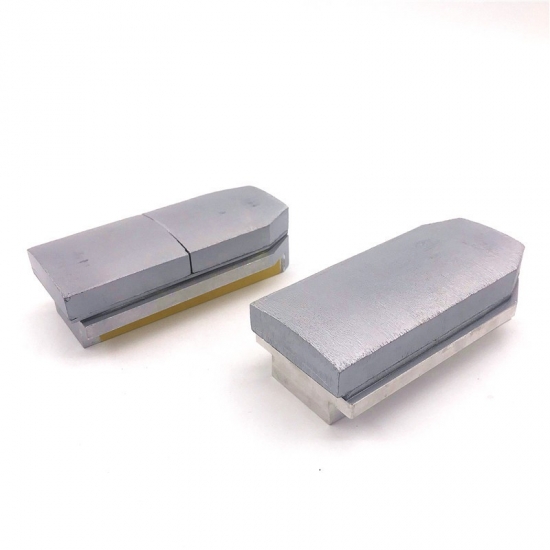

BUFF FICKERT ABRASIVE FOR GRANITE FINAL POLISHING

DESCRIPTION:

JINSHAN buff fickert abrasive is a resin bond LUX fickert abrasive for granite final polishing. There are black, grey and green buff fickert are available. Black buff fickert is mainly used for black or dark color granite, grey buff fickert is mainly used for light color granite, while green buff fickert can be used for universal granite. Compared to LUX fickert abrasive, it is low cost and it is supposed to get longer lasting shinning.

SPECIFICATIONS:

Length: 14cm, 17cm

Type: granite fickert abrasive

Available colors: black, grey, green

Available grit: LUX

Abrasive bond: resin bond

Attachment: plastic base

Application: To be used for final polishing granite slabs on automatic or semi-automatic polishing lines.

PACKING DETAILS:

1.24pcs each carton

2.Around 22kgs each carton

3.Carton size: 40x30x19cm

FEATURES:

1.Different formulas of segment will be offered for final polishing different kinds of granite slabs.

2.Special formula ensures a high gloss within a short time.

FAQ:

What is the differences between BUFF fickert and LUX fickert?

BUFF fickert and LUX fickert is made with different production technology. BUFF fickert is resin bond abrasive while LUX fickert is wool made pressed abrasive. The materials are different and the formation of the abrasive brick is also different. BUFF fickert is cheaper than LUX fickert, it is spposed to get longer lasing shinning while LUX fickert is to get higher glossy polishing on granite surface. You can make choices upon your request.

+86-595-22582118

+86-595-22582118 info@jinshanstone.com

info@jinshanstone.com

IPv6 network supported

IPv6 network supported